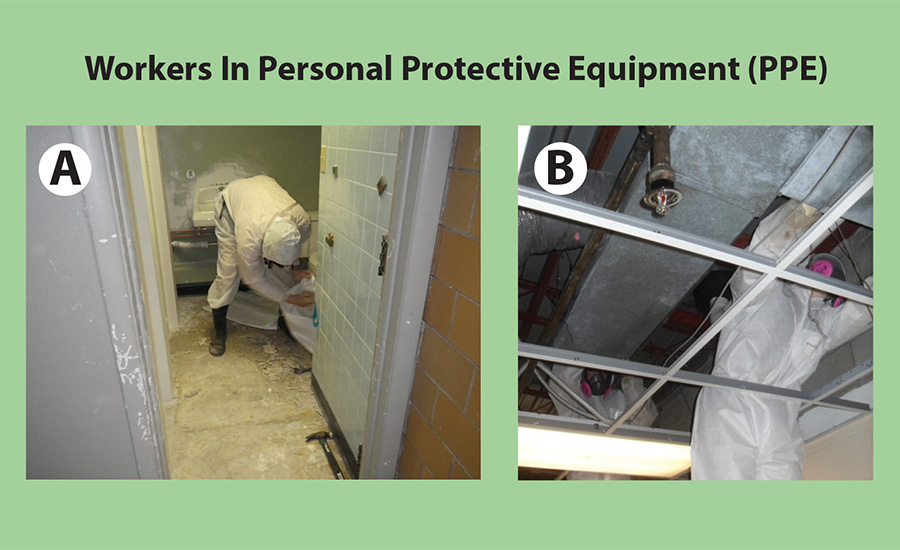

Although there are some substantive differences during execution of the work, there is no denying that many of the core concepts integrated into the current standard of care for mold remediation come from the asbestos abatement industry. Isolation of the work area, sealing of HVAC systems with critical barriers, the use of air filtration devices with HEPA filters (to exhaust air from the work area and thereby create negative pressure), utilizing HEPA-filtered vacuums for the capture of small particles, double-bagged debris to make sure that contamination does not go airborne when the waste is moved, the use of decontamination chambers, full-body suits to prevent cross-contamination, and more, are all standard practices that migrated from asbestos abatement to mold remediation.*

Negotiating a Regulatory Labyrinth

There is also a more direct connection between asbestos and the restoration industry. Depending on the age of the structure, there are federal, state, and local rules that require the identification and control of asbestos-containing building materials prior to disturbance. Many projects related to water intrusion or fire have been put into a holding pattern while waiting for the results of asbestos samples of finish material such as drywall, plaster, or textured ceilings.

Figure 2: MoldHold sheets were applied to one side to minimize possible asbestos exposure.

Worse yet, there is a general (although quiet) acknowledgment in the restoration industry that many projects move forward with flood cuts and removal of fire-damaged materials without proper identification of impacted materials which may contain asbestos. Even the installation of dehumidifiers and fans for drying (which create substantial air flow) can result in restoration contractors creating situations that are prohibited by various asbestos regulations.

OSHA Regulations

Specifically, directing the exhaust of an air filtration device (AFD) set up as a scrubber, or the air stream of a floor fan to create vortex drying against asbestos-containing material (ACM) can create a “disturbance” which is barred by numerous asbestos regulations. The first sentence of the definition of the word “disturbance” included in the OSHA Asbestos Standard for the Construction Industry is found in section 1926.1101(b) and reads as follows:

Disturbance means activities that disrupt the matrix of ACM or PACM, crumble or pulverize ACM or PACM, or generate visible debris from ACM or PACM.

There are two key parts of the definition which impact the restoration contractor. The first is the phrase “or generate visible debris”. This means that if the airflow from one of those scenarios described above results in visible specks being liberated from the material (whether it is actually asbestos or just house dust that was trapped on the surface), the contractor is liable for citation. This is not just a “slap on the wrist” citation. Depending on the jurisdiction, unwittingly disturbing building materials with asbestos can rack up fines as high as $25,000 per day!

The second part of that sentence concludes with the phrase “from ACM or PACM”. ACM was already described as asbestos-containing material, but putting a “P” in front of it changes the term to “presumed asbestos-containing material.” What this means is that if OSHA comes on-site and sees airflow blowing against a popcorn ceiling with dust in the air, the contractor can be cited unless they can proactively prove that the surface impacted by the airflow does not contain asbestos. Until they have the evidence in hand that damaged plaster/drywall, fractured floor tiles, or even intact textured ceiling (especially the more fragile “popcorn” style ceiling finish) does not contain asbestos, any disturbance must be avoided.

The EPA Has Asbestos Rules As Well

If dealing with federal and state occupational safety regulators was not enough, the federal EPA and their state counterparts also have specific asbestos regulations. Two aspects of their rules can have a major impact on restoration projects. Any asbestos disturbance that creates a “visible emission” of asbestos to the outside is a citable offense. Even inside a building, visible emissions outside of the designated work area can result in a citation as well. Nor is a one-time event exempt from many of the rules, as even accidental disturbances are classified under different EPA regulations as a “fiber release episode.” The EPA even has a required clearance level for specific projects in schools that 0.01 fibers per cubic meter of air (f/cc) are 10 times lower than the OSHA allowable asbestos fiber limit for workers.

Figure 3: Air samples were taken while air was being agitated to simulate disturbance from floor fans during drying.

Keeping Projects Moving Forward

Figure 4: Additional samples were collected while the asbestos ceiling was intentionally disturbed; in this case by using a broom.

Restoration contractors should also be aware that although older buildings have a higher likelihood of possessing asbestos-containing products, there is no officially recognized “cutoff date” for when asbestos was no longer used. As such, various regulatory agencies (particularly at the state and local level) have made it clear that asbestos inspections are necessary before any ACM or PACM is disturbed.

Obviously, stopping every water intrusion, fire, or mold project while waiting for sampling and the return of the laboratory results can significantly delay a project. While it is difficult to prevent disturbance when flood cuts or other materials need to be physically removed, there are a great many projects where preventing airflow disturbance of ACM or PACM could be a substantial benefit to the restoration contractor. This is where a reverse technology transfer (from the mold remediation industry back to the asbestos industry) can be a significant game-changer.

Desperation/Necessity Leads to Invention

In 2010, a homeowner with severe mold sensitivity wanted to be in his own home to coordinate with insurance adjustors and remediation professionals. He wanted first-hand involvement to address his mold situation safely so that he could move his family back home from a hotel. To avoid potential exposure, he applied a homemade adhesive to plastic sheeting which allowed the material to stick securely on the wet, moldy surfaces. The mold remediation contractor looking at this project was so impressed that he requested some for his own use and the MoldHold product was “born”.

After nearly a decade of use in the mold remediation industry, a representative from a large restoration company (that had just been cited for asbestos disturbance violation during a water loss) wondered if MoldHold could be useful for asbestos control. The manufacturers of the self-stick plastic took that as a challenge and looked for a “worst-case” scenario to determine if the product could be useful in an ancillary industry.

Testing to See if Fibers Could Be Controlled Under the Worst of Conditions

In December of 2019, a house undergoing renovation was identified as having an unpainted asbestos-containing popcorn ceiling in the bedroom that was very friable (i.e., able to be crumbled or pulverized by hand pressure). The site was used as a test location to determine if MoldHold could prevent asbestos fibers from getting in the air during drying and other restoration activities. A well-respected asbestos consultant was involved in the process to document the conditions and collect asbestos samples.

The bedroom with the asbestos ceiling was actually split in half with an isolation barrier. The ceiling on one half of the room was carefully covered with sheets of MoldHold. Air samples were collected on each side of the bedroom under two types of conditions (see figures 1-3).

It was important to determine what potential asbestos fiber concentrations would be with individuals moving about the work area as if they were packing up contents or doing an extraction. That sort of activity would represent more “normal” conditions; work steps that would not typically generate a lot of airborne fibers from friable asbestos material. The second simulated condition would be a water or fire restoration project that had moved on to the drying phase where dehumidifiers, negative air machines, and floor fans are utilized. The potential for this more aggressive air movement to dislodge fibers is well-documented in the asbestos literature. In this case, the airflow was simulated with a large box fan while the samples were being collected.

Figure 5: The MoldHold prevented worker exposure in case of an accidental impact with a tool or ladder; as simulated by the broom action used in both test spaces.

Impressive Results

The sample data was as good as what was anticipated by the makers of MoldHold. The chart below summarizes the information from the air samples. Note that phase contrast microscopy (PCM) is a type of asbestos fiber analysis that was done in the field. Although PCM can distinguish between fibers and other air particles, the method does not have the ability to specifically identify asbestos as compared to fiberglass, nylon, or other fibers often suspended in the air. Because of that, transmission electron microscopy (TEM) was used on some of the samples to confirm the presence or absence of actual asbestos.

|

MoldHold Test for Asbestos Summary of Air Sample Results** | |||

| Location/Description | PCM Results (f/cc) | TEM Results (s/mm2) | |

|

Room w/MoldHold |

Still Air Air Movement |

0.011 0.001 |

<0.001 <0.001 |

|

Room w/ no MoldHold |

Still Air Air Movement |

0.012 Over-loaded |

<0.002 Over-Loaded |

The sample results clearly illustrate the risk restoration workers face if they set up air moving equipment for dry-down in facilities with friable asbestos present. The variation in the air samples during activities simulating initial setup (where the air is relatively still without fans and blowers operating) is similar to both rooms with little exposure. The change in sample results was dramatic when a fan was added. Air sample results in the room that was not protected had so many fibers and particulate, that the samples were overloaded. This is a clear indication that the fiber concentration was well above the OSHA maximum limit of 0.1 fibers per cubic centimeter of air (f/cc).

Figure 6: Black plastic was put down to show the contrast with the ceiling debris, but no particles were visible after brooming the ceiling of the room with MoldHold.

Figure 7: The visual evidence of the effects of accidental disturbance was dramatic with substantial debris on the floor of the room with no MoldHold.

Looking at it from the reverse perspective, applying the sheets of self-stick plastic resulted in a work area that eliminated the worry about any fiber release episode, even when extensive air movement was intentionally introduced into the project. The MoldHold was such an effective containment barrier, that even with aggressive air movement in the contained area, fiber concentrations never exceeded the EPA clearance level for school abatement projects.

Still More Good News

The fact that the barrier system showed real promise in minimizing potential asbestos contamination during simulated water or fire restoration activities was certainly exciting. A bit of a bonus was the fact that after the simulation related to a fire or water loss was completed, another test was conducted. The ceilings in each of the contained areas (one with MoldHold and one without), were intentionally impacted in order to simulate a potential fiber release episode. In this particular case, a broom was used to sweep across the surfaces. This activity was conducted to simulate what would happen in the case of an accidental impact to the ceiling from a tool or ladder.

Several steps were taken to make sure that the procedures provided a reasonable representation of conditions after the intentional fiber release episode. Before any disturbance with a broom, black plastic was laid on the floor. The dark color would provide a much greater visual contrast for the white popcorn ceiling, if any was dislodged. The individuals conducting the tests were also careful to apply approximately the same pressure over a similar square footage of the ceiling in both isolated areas. The activities are illustrated in figures 4 - 7 with sample results summarized in the table below. Note that no surface samples were collected from the room with MoldHold on the ceiling, because there was no visible debris on the floor after the work activity was completed.

|

MoldHold Test for Asbestos Summary of Floor Surface Results (Visual Data & MicroVac)** | |||

| Location/Description | Visual Results (on black background) | Asbestos Structures-Chrysotile | Asbestos Concentration (s/cm2) Chrysotile |

| Room with MoldHold | No particulates | No sample collected | No sample collected |

| Room without MoldHold |

Extensive particulates |

915 111 |

594,156 72,078 |

The results of the testing to simulate a fiber release episode led to further possible uses for the MoldHold in asbestos abatement work. It is clear from the sample results that if the barrier was placed on the asbestos ceilings as they were being removed, airborne fiber concentrations and visible emissions would be significantly reduced. The popcorn ceiling and the substrate could be removed as a single unit, resulting in a cleaner, safer workplace. After cutting sections of the ceiling down and scoring the back of the drywall, the asbestos abatement workers could simply fold sections of the removed ceiling in on itself before bagging, to keep airborne fibers to a near-zero level. To follow EPA and OSHA regulations, the removed ceiling would still have to be thoroughly wetted after it was placed in disposal bags.

Building on a Good Idea and Solid Data

Given this success, the manufacturers of Mold Hold have continued to adjust their product and have rebranded the newest version as Asbestos Shield. Truly, this is a gift back to the asbestos abatement industry from the mold remediation world.

*Of course, those with a deep knowledge of the history of safety and contaminant control know that many of the principal protective activities utilized for asbestos work were initially developed during World War II, for the control of radiological contaminants as part of the Manhattan Project to build the first atomic bombs. These techniques (and the specialized equipment that they required) were then refined as they spread out to other industries with small airborne contaminants, such as asbestos abatement, cleanup of heavy metals, lead paint removal, and mold remediation.

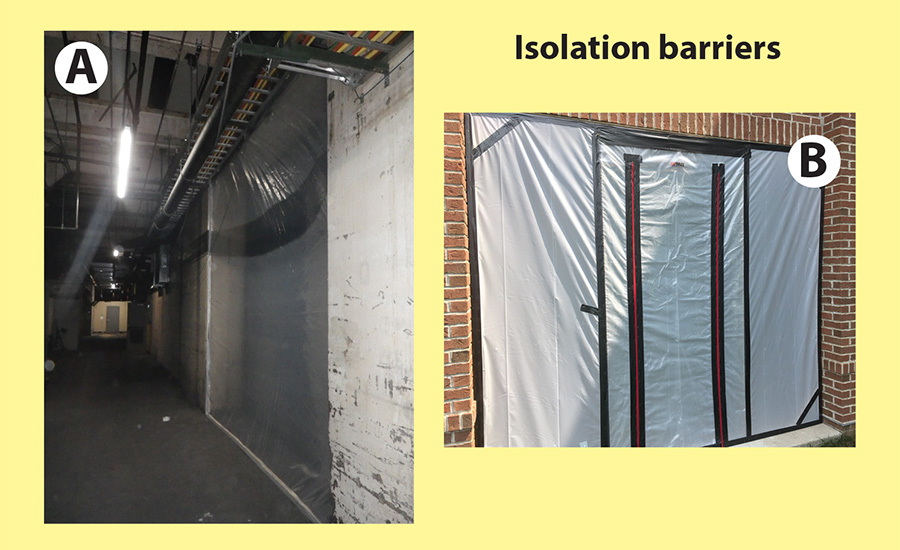

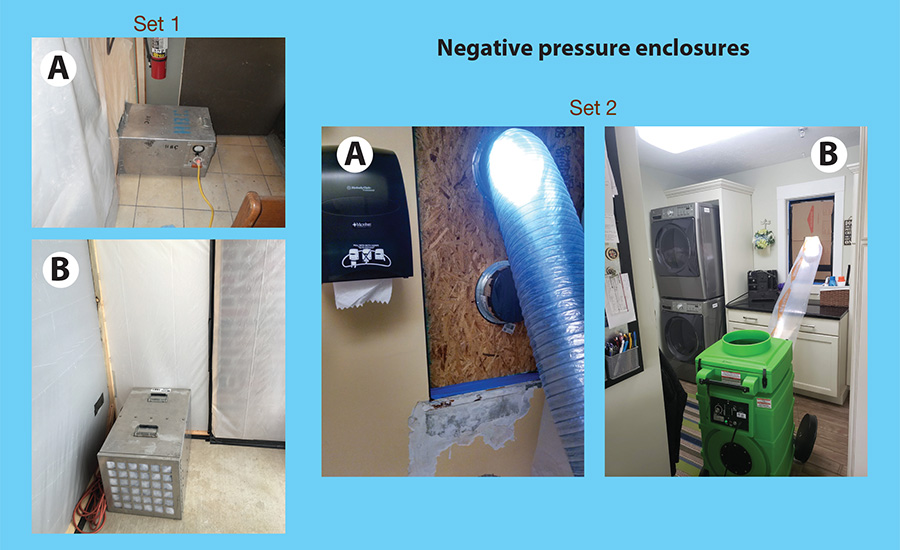

Asbestos vs. Mold Remediation Containment: Can You Decide Which is Which?

To illustrate some of the similarities between asbestos abatement and mold remediation, look at each pair of photos and decide which ones come from asbestos abatement projects and which ones from mold remediation jobs. The answers may surprise you! When you’re done, email [email protected] for the answers!!